The new set of batteries arrived. Testing of the batteries were conducted to determine whether batteries would be compatible with the charging components. The batteries and charger are compatible. A warning label rates max charge rate at 700 mA and that a higher rate will overheat the battery. Trickle charging was also mentioned on the label. The charger has the ability to set the charge rate to 700 mA.

Wednesday, May 10, 2017

New Batteries

The new set of batteries arrived. Testing of the batteries were conducted to determine whether batteries would be compatible with the charging components. The batteries and charger are compatible. A warning label rates max charge rate at 700 mA and that a higher rate will overheat the battery. Trickle charging was also mentioned on the label. The charger has the ability to set the charge rate to 700 mA.

Tuesday, May 2, 2017

15 Days Till Maker's Faire

The second was completed over the weekend. Additional parts for the rack and support were purchased. Hardware and material for the battery box for the second solar rack was also purchased and ready for fabrication.

Additional batteries were purchased after further discussion with Chris to determine the best solution for the limited funds available. It was determined that 5 cell AA 6V 2500 mAh NiMH were the best option. Six units were purchased and will arrive by end of this week or early next week. Charging tests will have to be ran once the batteries arrive.

The goal for the remainder of this week is to finish fabrication of the second battery box along with mounting the electrical charging components.

Tuesday, April 25, 2017

Testing, Procurement, Fabrication

The second set of charging components were tested on two different occasions. All components functioned properly. The wiring connections between components will need to be replaced as most of the wiring were either missing, damaged, or improperly stripped when received. Crimped spade connectors will be used at the ends of each wire that connects to screw-down connectors. Exposed opposite polarity wires in close proximity to each other is a safety hazard that must be avoided.

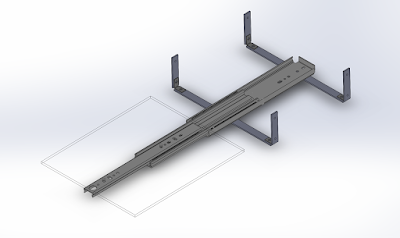

Materials and hardware were purchased last week and dropped off to Kevin from the Manufacturing Team to construct the second solar panel rack. Half of the first rack was also borrowed to modeled off of to build the second. I will be responsible for the purchasing and fabricating the battery box to store charging components once wiring is sorted. The latest progress is pictured below.

Materials and hardware were purchased last week and dropped off to Kevin from the Manufacturing Team to construct the second solar panel rack. Half of the first rack was also borrowed to modeled off of to build the second. I will be responsible for the purchasing and fabricating the battery box to store charging components once wiring is sorted. The latest progress is pictured below.

In response to the low run time of batteries reported by Chris from the Controls Team, new batteries will be purchased. Battery selection began with analysis of the conditions and system the batteries will operate in. The motors on the pod cars have a maximum voltage input of 6 volts. The spacing within the cabins of podcars are limited to about a volume of approximately 16 square inches. After discussing with Eric, the budget for new batteries are limited approximately $100. Two different chemical composition of batteries were explored.

The first battery examined are a pair of 18650 lithium ion (Li-ion). In order to use this battery, each pod car would require a step-down voltage regulator. This additional component for each podcar increased cost significantly and minimized the amount of batteries that could be purchased with the remaining budget.

The other option is to purchase batteries similar to the 4 cell 4.8V nickel-metal hydride. For roughly $14 each, a 5 cell 6 V nickel-metal hydride battery pack can be purchased that has a nominal capacity of 2500 mAh. With a budget of $100, 7 batteries can be purchased that would be directly compatible with both the charging system and pod car system.

Friday, April 21, 2017

Tuesday, April 18, 2017

Post-Paseo

After presenting at Paseo Public Prototyping Fair, there

were several issues that the Small Scale Teams would like to be addressed

before Maker’s Faire. The runtime per battery were roughly 20 to 30 minutes

according to Chris from the Controls Team. With a charge time of an hour, the

rate of energy usage is double that a solar panel can recharge the battery. The

goal is to achieve 100% renewable energy for the 1/12 scale Spartan Superway

model.

A simple solution to increase the amount of solar energy converted

to charge batteries is to utilize an additional solar panel. Two solar panels

will allow the system to charge two batteries fully within an hour. This second

solar panel was also a planned deliverable since the beginning of this project.

Being a team of only one person, constructing a second solar

rack to house and support a second solar panel would take up tremendous amount

of time. The condition and functionality of the second set of charging

components are unknown and will need to be tested. These components will be

tested and replaced if needed. In order accomplish this goal in a timely manner,

I’ve enlisted the help of Kevin from the Track Manufacturing Team. Kevin agreed

to help construct the second solar rack. I am to provide all materials necessary.

By using leftover materials from the first solar rack, I have created a Bill of

Material. Materials will be purchased this week and dropped off to Kevin along

with the constructed solar rack.

Tuesday, April 4, 2017

Spring Break

Solar panel support frame fabrication began with cutting

aluminum bar stock down to proper lengths. Each half of the support frame consists

of (2) 5 feet and (4) 1 foot pieces. Two L-brackets were used at each corner to

form a rectangular box frame. Holes were drilled for bolts and nuts to mate

L-brackets and aluminum bar stock.

Holes were drilled for bolts and nuts to mate the two box

frames together. With the two halves constructed and connected, measurements

were made to place the supports that will connect to the two tilting mechanisms.

The placement of the ribs were laid out to avoid interfere with supports. Holes

were drilled on the sides of the frames, ribs, and clamps. Adjustments were made

to ensure there was enough room to slide the solar panel between the ribs and

clamp.

Acrylic panels were purchase to fabricate a box to house the

charging components. These pieces will need to be cut down to dimension and

bolted together. With the box fabricated and sliders attached to the box, the

position and placement can be determined to make connections onto the solar

panel frame.

Monday, March 13, 2017

Week 6

Procurement:

Hardware for the mate the ribs and clamps on to the rack were purchased. The match die and drill bit were sourced from home. Bolts for to mate the solar racks were also purchased. The hinges for the acrylic box were purchased. The next step for fabrication is cut the aluminum stock down to size for the sides of the rack along with the supporting joints. Once down to size, the aluminum stock will be drilled and tapped.

Fabrication:

Several more of the 6 cell batteries were downsized to 4 cells.

Testing:

The newly modified 4 cell batteries were tested over the weekend. Several discharge and recharge cycles were placed on the batteries. It was determined with approximated 60 watts and 1 amp output from the solar panels, a battery would be fully charged with 5.86 volts and 2222 mAh energy capacity under a hour.

Hardware for the mate the ribs and clamps on to the rack were purchased. The match die and drill bit were sourced from home. Bolts for to mate the solar racks were also purchased. The hinges for the acrylic box were purchased. The next step for fabrication is cut the aluminum stock down to size for the sides of the rack along with the supporting joints. Once down to size, the aluminum stock will be drilled and tapped.

Fabrication:

Several more of the 6 cell batteries were downsized to 4 cells.

Testing:

The newly modified 4 cell batteries were tested over the weekend. Several discharge and recharge cycles were placed on the batteries. It was determined with approximated 60 watts and 1 amp output from the solar panels, a battery would be fully charged with 5.86 volts and 2222 mAh energy capacity under a hour.

Monday, March 6, 2017

Week 5

It was decided to reduce the batteries from 6 cells to 4 cells in order to drop the voltage. This would allow the motors powering the bogie to be ran directly off the batteries without requiring a buck converter. Modifications were made to prototype a 4 cell battery from a 6 cell battery. This battery was tested to be capable of powering the Arduino, sensors, and motors. Before retrofitting more 4 cell batteries, I tested this prototype battery over the weekend to ensure charging components are compatible. The weather this weekend was terrible with random showers throughout both days. A brief window of direct sunlight allowed me to charge the battery to roughly 15 minutes.

Over the weekend, the connectors for the batteries and associated components arrived. Heat shrink wrap for additional battery modifications were purchased. I can begin making modifications to all the batteries and associated connections.

The manufacturing team created a prototype of the overlaying rib. This design of the rib will allow the rib to bolted down along with a clamp instead of needing to weld. The fitment of the rib was tested with the solar panel clamped onto the rib. The edge of the solar panel needs to rest on the rib without any overlap passed the bend of the rib.

Over the weekend, the connectors for the batteries and associated components arrived. Heat shrink wrap for additional battery modifications were purchased. I can begin making modifications to all the batteries and associated connections.

The manufacturing team created a prototype of the overlaying rib. This design of the rib will allow the rib to bolted down along with a clamp instead of needing to weld. The fitment of the rib was tested with the solar panel clamped onto the rib. The edge of the solar panel needs to rest on the rib without any overlap passed the bend of the rib.

Wednesday, March 1, 2017

Week 4

Solar Racking Design:

New changes were made after last week's discussion. The track team expressed doubts of welding. In order to alleviate any extra burden on welding the solar racks, the design was changed so that the ribs could be bolted into place. This new idea was explored with the manufacturing team as the ribs will be produced by Kevin.

A clamp created to sandwich the solar panel between the clamp and ribs. The clamp are adjustable and uses the same hardware to bolt down the ribs onto the rack. Rubber inserts will be placed between the clamp and solar panel to prevent damages while promoting clamping force.

There are still a few minor tweaks that will be needed implemented to finalize the Solidwork design. The design should be completed this week.

Procurement:

A new connector for the modified 4 cell batteries were decided with the Controls team. 11 sets of connectors were order for bogies, charging modules, and batteries. The new 4 cell batteries will need to be shrink wrapped. Proper sized shrink wrap will be purchased locally.

New changes were made after last week's discussion. The track team expressed doubts of welding. In order to alleviate any extra burden on welding the solar racks, the design was changed so that the ribs could be bolted into place. This new idea was explored with the manufacturing team as the ribs will be produced by Kevin.

A clamp created to sandwich the solar panel between the clamp and ribs. The clamp are adjustable and uses the same hardware to bolt down the ribs onto the rack. Rubber inserts will be placed between the clamp and solar panel to prevent damages while promoting clamping force.

There are still a few minor tweaks that will be needed implemented to finalize the Solidwork design. The design should be completed this week.

Procurement:

A new connector for the modified 4 cell batteries were decided with the Controls team. 11 sets of connectors were order for bogies, charging modules, and batteries. The new 4 cell batteries will need to be shrink wrapped. Proper sized shrink wrap will be purchased locally.

Wednesday, February 22, 2017

Week 3 Project Update

Design:

With the design approval, calculations of required amount of materials were established. The quantities of aluminum stock was communicated with the track team. Currently, waiting for a response to determine if more material needs to be purchased from Coastal Aluminum. Confirmed with the track improvement team that the ribs will need to be fabricated according to previously mentioned specifications. Measurement of charging components and supporting hinged box were made to create a Solidwork design. The solar rack design still needs minor improvements to the mating of the two separate pieces before completion.

Procurement/Fabrication:

Position locking draw slider was purchased to match the physical dimensions of the solar rack and charging components. I am hoping to have all designs finalized by the first presentation. With that part complete, fabrication of components can begin that weekend.

T-bar:

A new idea of the modifying the supports proposed to the track team. An additional clamping plate between the T-bar and the 3-bar linkage can shift of the weight of the rack further in towards the center or outer perimeter of track loop to help with any stability issues.

With the design approval, calculations of required amount of materials were established. The quantities of aluminum stock was communicated with the track team. Currently, waiting for a response to determine if more material needs to be purchased from Coastal Aluminum. Confirmed with the track improvement team that the ribs will need to be fabricated according to previously mentioned specifications. Measurement of charging components and supporting hinged box were made to create a Solidwork design. The solar rack design still needs minor improvements to the mating of the two separate pieces before completion.

Procurement/Fabrication:

Position locking draw slider was purchased to match the physical dimensions of the solar rack and charging components. I am hoping to have all designs finalized by the first presentation. With that part complete, fabrication of components can begin that weekend.

T-bar:

A new idea of the modifying the supports proposed to the track team. An additional clamping plate between the T-bar and the 3-bar linkage can shift of the weight of the rack further in towards the center or outer perimeter of track loop to help with any stability issues.

Monday, February 13, 2017

Week 2 Updates

This week, I was able to charge a battery fully to determine the maximum voltage.

The initial voltage of the battery was 7.44 V.

The maximum voltage of the battery was 8.59 V after 67 minutes of charging. Further charging did not increase the voltage reading of the battery.

Several issues were discussed with the track manufacturing team:

- Ribs for the solar rack: arc length, radius, amount of pieces

- Modifications to the T-bar pole mount to allow adjustment of positioning

- Available materials left over

The controls team was informed of the battery that will be used to power the bogies. A battery was given to Chris, who has a charger, to test the controls using the rechargeable battery. Several more will be given to Luis for backup.

The bogie team was also informed of the battery size. The position of the battery will be inside the cabin.

The design of the solar panel rack begun. Measurements and dimensions of the pieces forming the rack were taken and imposed into SolidWorks. Previous year's T-bar pole mount was mated to the new rack.

A clamp system will need to be implemented to secure the solar panel onto the rack. The battery box design will need to be updated to a box design with a hinge.

Monday, February 6, 2017

Battery Charging Test

The objective for the first 2 weeks of this semester was to test charge the batteries and ensure functionality. Due to weather conditions being rainy and cloudy generally throughout the past 2 weeks, the only window I've found to test the equipment was on Saturday and Sunday. First, I began by checking the voltage of the combined 6 cell battery. The battery's initial voltage was 7.56V.

After about roughly 3 hours with numerous resetting of the charging unit, the voltage of the battery was 8.10 V. These resets were caused by dense clouds or other obstacles preventing the solar cells from producing enough power which results in a voltage drop across the circuit. Due to these resets, the time period of charging is unknown. Future plans will feature a recording device so that the exact time when charging stops will be known. The specifications for the iMAXB6AC states the allowable DC input voltage is 11-18V. The buck converter was set to 17.9V, the highest allowable voltage output (input into iMAXB6AC) to delay the "DC IN TOO LOW" error message which stops the charging process because of the insufficient sun light. According to the manual this error is caused by the input voltage being less than 11V.

Without any battery voltage charge chart, it is difficult to determine the state of charge (SoC) of the battery as the relationship between voltage and SoC is exponential. Only references I found for 7.2V nominal batteries were stating that a fully charged battery would measure ~8.4V. The goal of the next testing session is to determine the maximum voltage the batteries will reach and time it takes to reach this maximum voltage.

Thursday, January 19, 2017

Solutions to Mounting Batteries

A simple and low cost solution to mount the battery packs to the board containing charging components is to use Velcro straps. With cuts on the sides of a rectangular retaining box for the strap to loop around, the battery will be in locked position with minimum movement.

This design uses a locking latch along with a hinge to form a door that could be closed and opened. An enclosure underneath the board keeps the battery in place while allowing access from above.

Similar to the design above, the battery pack is housed in an enclosure with an access door. The door is held closed using a push latch. The latch clamps down on the ball mounted onto the door when force is applied. The latch releases ball also with the application of force. This design will give the board a flush look with much of bulk placed behind the board.

Saturday, January 14, 2017

After noticing unistruts used to secured electrical wiring, this design was created. An unistrut is utilized on each side. The board is mounted onto two trolleys with 4 3/8 bolts and nuts. The unistruts will be mounted to the solar frame in similar fashion.

This design uses a pair of side mount drawer slide to mount the board containing the solar charging components. The biggest advantage of using side mounted drawer slide will be the two locking positions offered. The wheels are locked into place in the fully extended and fully closed positions. These rails are available off the shelf with different lengths.

Sunday, January 8, 2017

A bottom mounted drawer slide is used to provide the linear motion of the board containing the charging components. The slide is attached to a pair of brackets which are mounted directly to the solar rack. Each pair of bracket consist of 2 corner brackets and 3 pieces of aluminum rails. The corner brackets and aluminum rails are joined together with #8 screws. The slider, board, and brackets are joined together with #6 screws. The dimensions of the aluminum rails are the same dimensions of the upper rail of the track.

A similar design utilizing side mounted drawer slides is being worked on.

A similar design utilizing side mounted drawer slides is being worked on.

Subscribe to:

Posts (Atom)